Our Process

Offering top quality Venezuelan Fine Flavor Cocoa is a challenge that requires planning, time and the hard work of our Agriculture Professionals and experts linked to Cocoa.

Through the combination of ancestral practices and the use of new technologies we consistently obtain the flavors and aromas that characterize our Fine Flavor Cocoas. At Terracao, we carry out a rigorous traceability process. We take part of every detail in all the stages of the production process, guaranteeing our clients, a consistent and extraordinary final product.

Establishment

The best seeds, by themselves, do not guarantee a better product. An ideal Cocoa plantation must be based on unique genetics appropriate to the land where they are planted. However, for it to be truly special, environmentally responsible farming techniques must be used to allow for the soil’s adaptation and recovery, maximizing the development of healthy and productive plants. As part of this process, our team of Agricultural Engineers and Technicians constantly carry out inspections and on-going trainings in the plantations of our Associate Farmers.

Maintanence

Proper agricultural practices are crucial for Cocoa trees to develop their full potential, allowing the healthy growth of its fruits. Planned pre-harvest works, like pruning, weeding, pest controls and organic fertilization among others are key to ensuring a healthy cultivation. At TERRACAO we rely on a team of experts who constantly advise and work side by side with our Associate Farmers during this vital stage.

Harvest

Once the fruits reach the optimum ripeness and are ready to be collected, the harvest feast begins. This stage generates great joy in all those involved in the production chain, especially in our Associate Farmers, since all their years’ hard work is finally paying off. Appropriate tools must be used during this process to collect both the healthy and unhealthy fruits of the plant, making sure to separate them later. The healthy fruits will be broken to obtain a clean white wet Cocoa mass that will be used for the Fermentation Process. Diseased fruits will be removed from the plantation to avoid additional strains.

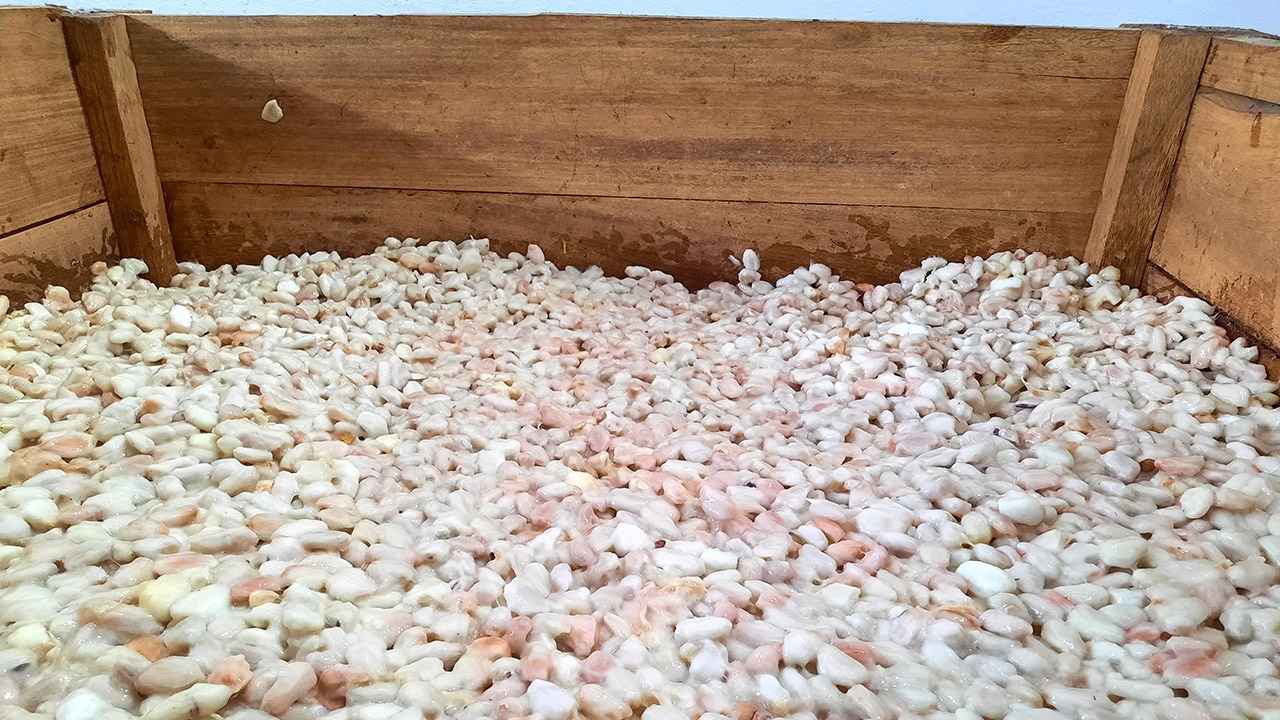

Fermentación

Key phase for Fine Flavor Cocoa development, in which freshly harvested seeds, still covered with mucilage, are placed in sweet wooden boxes to be subjected to the established Fermentation Process, according to the Cocoa variety and location or to our Client’s requirements. In this stage, a series of fundamental biochemical changes take place where the flavor and aroma precursors of each Cocoa variety will develop, giving rise to our products of exceptional quality.

Sun Drying

Once the beans reach the ideal fermentation point, according to the Cocoa variety that’s being processed or to our Client’s requirement, we proceed to the Natural Sun Drying Process that takes place in sweet wooden beds. The sun is the undisputed protagonist of this decisive stage. This process needs to be done gradually, so that the flavor and aroma precursors finish consolidating, allowing them to reach adequate humidity levels that range between 7% and 7.5%, a key factor for quality assurance.

Cleaning and Selection

At the end of the Natural Sun Drying Process, all Cocoa beans are subjected to a rigorous Selection Process (manual and/or automated) to ensure that they meet our Clients’ requirements. The most important aspects to consider during this process are: bean size and uniformity, moisture content, presence of foreign matter, presence of fungi, presence of infested beans, presence of brown beans, % of fermented beans, % of violet beans and % of slaty beans. All these criteria are carefully monitored by our Specialized Technical Team during the Selection Process in order to fully comply with the established protocols.